Overview of Standard Wire Gauge

History and development of wire gauge systems

Wire gauge systems have a history dating back to the 19th century, driven by the need for standardized wire sizes. Originating in 1857, the Birmingham Wire Gauge (BWG) addressed industrial demands for uniformity. Subsequently, it evolved into the Standard Wire Gauge (SWG) in 1880, which was widely adopted in Britain and its colonies. Meanwhile, the United States developed its own system, the American Wire Gauge (AWG). These developments supported industrialization, infrastructure expansion, and manufacturing. Today, wire gauge systems are crucial for ensuring compatibility, efficiency, and safety in engineering and manufacturing.

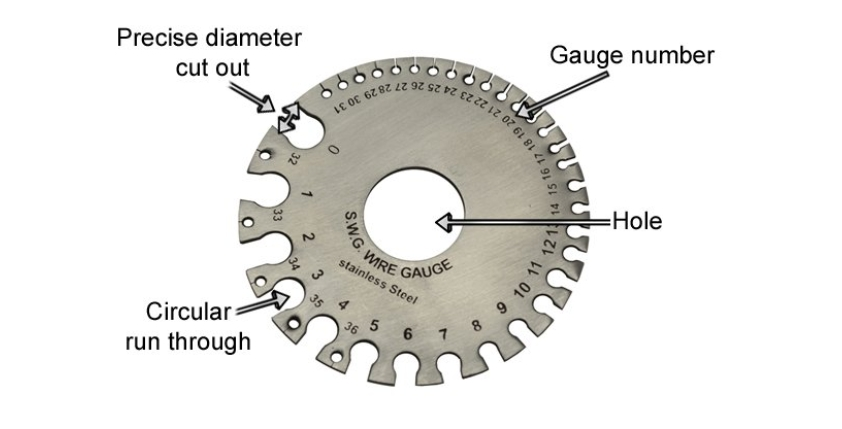

Explanation of How Wire Gauge is Determined

Wire gauge systems originated in the 19th century to standardize wire diameters across industries. In 1857, the Birmingham Wire Gauge (BWG) emerged in England to ensure consistent wire sizes. Subsequently, it evolved into the Standard Wire Gauge (SWG) in 1880, which was widely adopted in Britain and its colonies. Meanwhile, the United States developed its own system, the American Wire Gauge (AWG). These systems collectively supported industrialization, infrastructure expansion, telecommunications, and manufacturing. Today, wire gauge remains crucial for ensuring compatibility, efficiency, and safety in diverse applications.

Comparison of American Wire Gauge (AWG) and Other Gauge Systems

Breakdown of Different Wire Gauge Sizes

Wire gauge sizes encompass a range of diameters used for various applications. Typically, these sizes are categorized numerically, where lower numbers represent thicker wires and higher numbers indicate thinner wires. For instance, common wire gauge sizes include:

Larger Gauge Numbers (Thinner Wires):

- Higher gauge numbers, such as 24 AWG or 30 AWG, denote thinner wires commonly used for applications like electronics, telecommunications, and small appliances.

- These wires are suitable for carrying low currents and are often used in intricate circuitry and connections where space is limited.

Intermediate Gauge Numbers:

- Gauge numbers like 16 AWG or 20 AWG represent intermediate thicknesses, frequently employed in household wiring, automotive applications, and general-purpose electrical installations.

- These wires strike a balance between current-carrying capacity, flexibility, and ease of handling, making them versatile for various indoor and outdoor uses.

Smaller Gauge Numbers (Thicker Wires):

- Lower gauge numbers, such as 6 AWG or 10 AWG, indicate thicker wires suited for high-current applications like industrial machinery, power distribution, and heavy-duty electrical installations.

- Thicker wires offer lower resistance, allowing them to carry larger currents over longer distances without significant voltage drops.

Comparison of American Wire Gauge (AWG) and Other Gauge Systems

American Wire Gauge (AWG):

- Widely used in the United States and North America, AWG is a standardized wire gauge system with a specific set of gauge sizes and corresponding diameters.

- AWG sizes are defined by a logarithmic formula, where each step in gauge number corresponds to a consistent change in wire diameter.

- This system is commonly used in electrical engineering, electronics, telecommunications, and automotive industries.

Other Gauge Systems:

- While AWG is prevalent in North America, other regions may utilize different wire gauge systems, such as the Standard Wire Gauge (SWG) in Britain and the Imperial Standard Wire Gauge (ISWG) in some European countries.

- These systems may have slightly different gauge sizes and measurement standards but serve a similar purpose of standardizing wire diameters for specific applications.

- Despite variations in gauge systems, conversion tables and formulas are available to facilitate cross-referencing and compatibility between different standards.

Applications

Common Uses in Electrical Wiring and Circuitry

Standard wire gauge (SWG) finds widespread application in electrical wiring and circuitry across various sectors. Some common uses include:

Household Wiring:

- SWG wires are utilized in residential buildings for electrical installations, such as lighting, outlets, and appliances.

- They are available in different gauge sizes to accommodate various current-carrying requirements and installation needs.

Electronic Devices:

- SWG wires are employed in the manufacturing of electronic devices, including computers, televisions, smartphones, and other consumer electronics.

- Thinner gauge wires are often used for internal connections and circuitry within these devices.

Automotive Wiring:

- SWG wires are utilized in automotive electrical systems for powering lights, ignition systems, sensors, and other components.

- They withstand vibrations and harsh operating conditions, making them suitable for use in vehicles.

Telecommunications:

- SWG wires are essential in telecommunications infrastructure for transmitting signals in telephone lines, internet connections, and networking cables.

- They facilitate the transmission of data and communication signals over long distances with minimal signal loss.

Industrial and Commercial Applications

Standard wire gauge (SWG) is extensively utilized in industrial and commercial settings for a variety of applications, including:

Industrial Machinery:

- SWG wires are used in industrial machinery and equipment for power distribution, control systems, and automation.

- They provide reliable electrical connections to motors, sensors, and other components in manufacturing processes.

Construction and Infrastructure:

- SWG wires are employed in construction projects for powering lighting, HVAC systems, and other electrical installations in commercial buildings, factories, and infrastructure facilities.

- They meet building code requirements and safety standards for electrical wiring in commercial and industrial settings.

Power Distribution:

- SWG wires play a crucial role in power distribution networks, transmitting electricity from substations to commercial and industrial facilities.

- They are used in overhead and underground distribution lines, transformers, and switchgear for delivering electricity to end-users.

Renewable Energy Systems:

- SWG wires are integral components in renewable energy systems, such as solar panels, wind turbines, and battery storage systems.

- They connect solar panels to inverters, wind turbine generators to electrical grids, and batteries to power conversion equipment, facilitating the generation and distribution of clean energy.